Advantages of a Lang's Lay.

The picture above illustrates how the axis of the individual wires relates to the axis of a rope in ordinary/regular and Lang's lay strands.

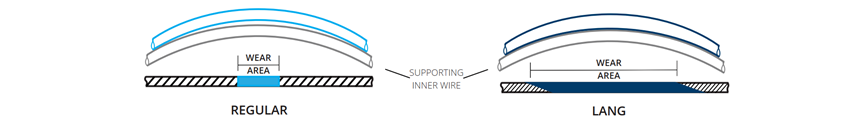

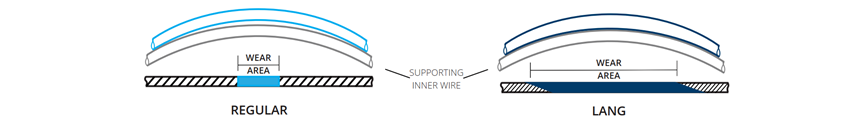

Bend fatigue, as a wire rope passes over sheaves, both the wire rope and the individual wires within the rope are subjected to bending. Since the individual wires within an ordinary lay rope are on the same axis as the rope, the same degree of bend is imposed on the crowns of the outer wires. Comparing the length of individual wires exposed from valley to valley, as illustrated below, the wires are significantly longer in the Lang’s lay rope. Therefore, the bending of a Lang’s lay rope results in less axial bending of the outer wires and an increase in bending fatigue performance. Additionally, the worn crown together with the shorter exposed length, allows the wire to spring away from the rope axis, further reducing the bend fatigue performance of an ordinary lay rope. Alternative descriptions for the direction and type of rope lay Right hand ordinary lay (RHOL) Right hand regular lay (RHRL) sZ Left hand ordinary lay (LHOL) Left hand regular lay (LHRL) sZ Right hand Lang’s lay (RHLL) zZ Left hand Lang’s lay (LHLL) sS Advantages of a Lang’s lay.

Resistance to wear, wires within an ordinary lay rope are subject of higher unit pressure which increases the rate of wear on both the wires within the rope and the contacting surfaces of the sheaves and drums. Therefore, the larger exposed surface area of the individual wires within a Lang’s lay rope provides the Lang’s lay ropes with better wear resistance and resistance to abrasion.

Disadvantages of a Lang's Lay Rope.

Resistance to crushing, Lang’s lay ropes are more sensitive to crushing and less robust.

Rotational characteristics, Lang’s lay ropes generate a higher torque moment due to the wires and strands being twisted in the same direction and have an increased tendency to turn (untwist) in-service and therefore single layer Lang’s lay construction ropes, e.g. 6 & 8 strand, should only be used when both ends of the rope are fixed, prevented from rotating.

Further guidance is available at contact@bridon-bekaert.com

Reference: TB.004 Ed.1 Dec 2021