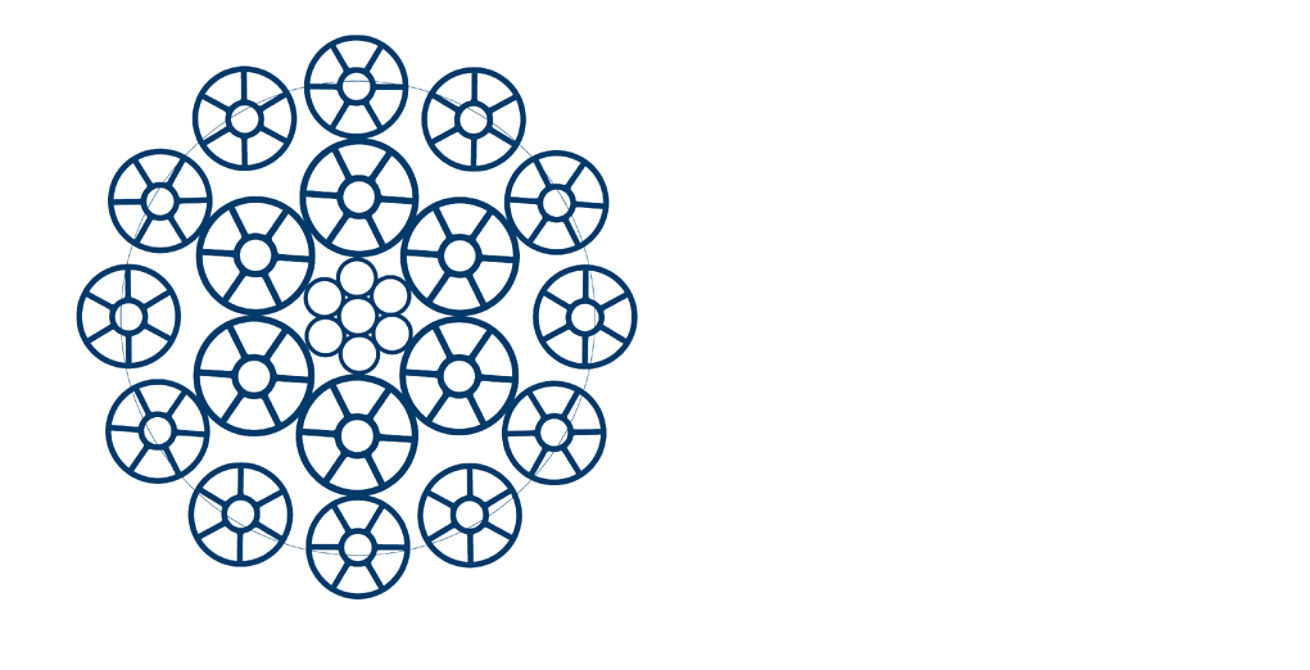

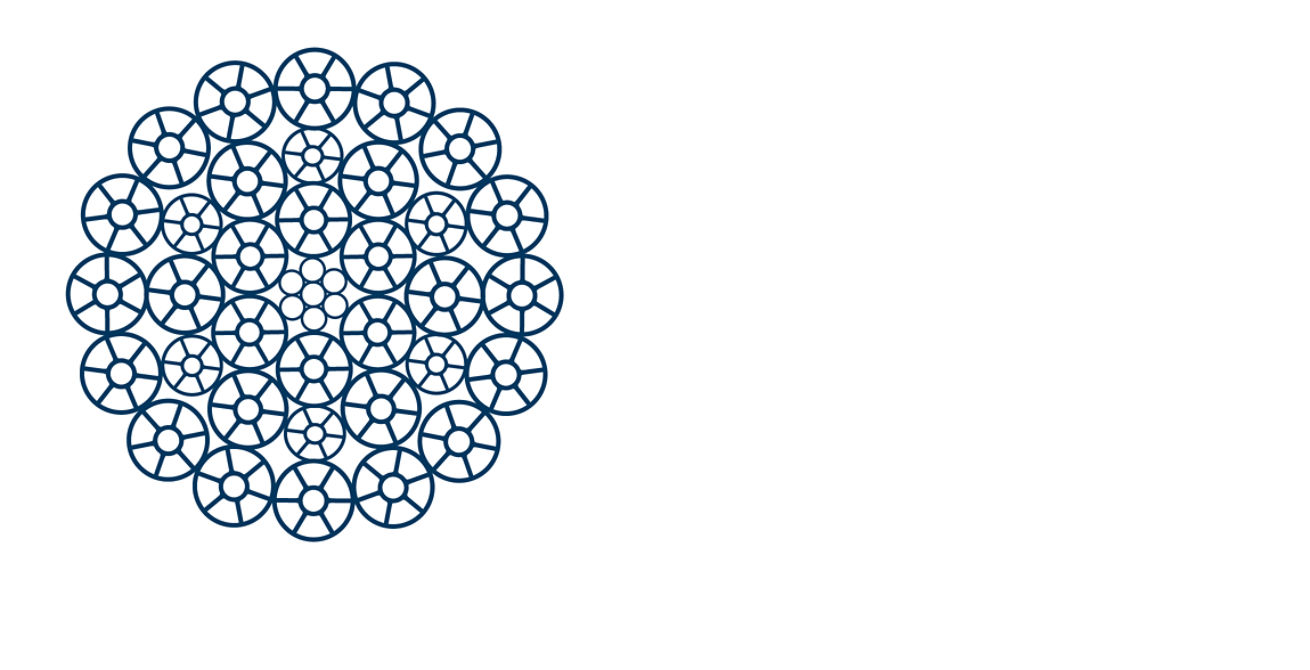

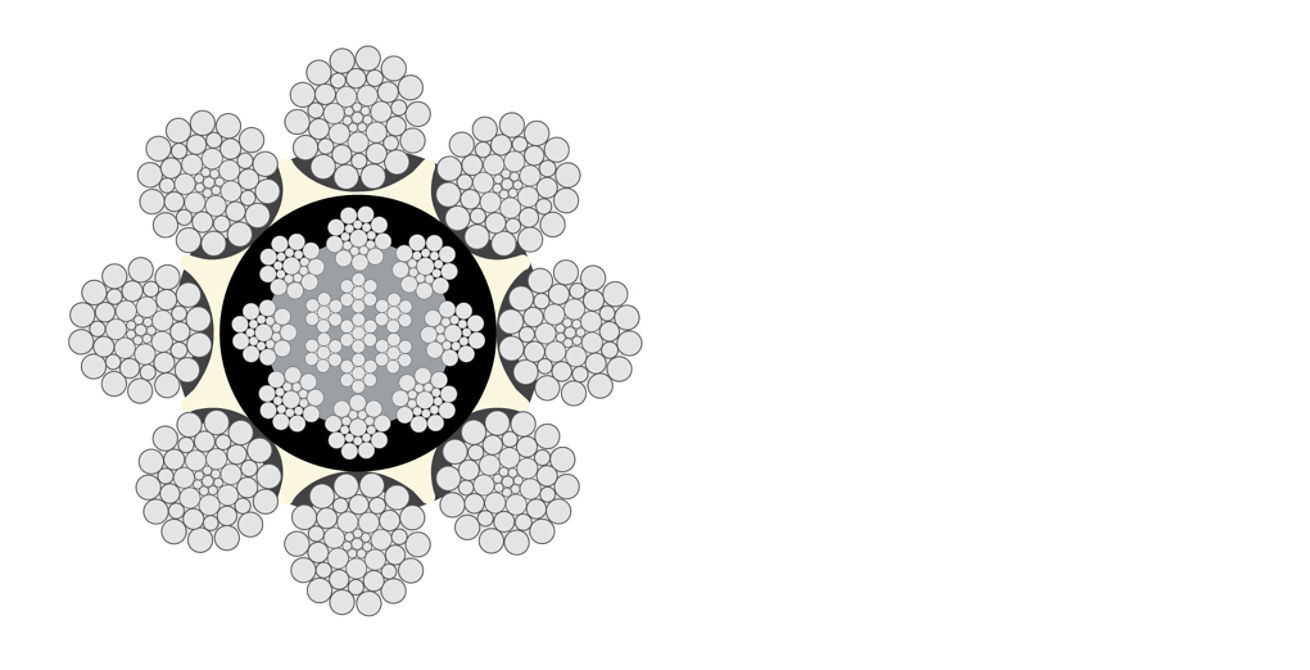

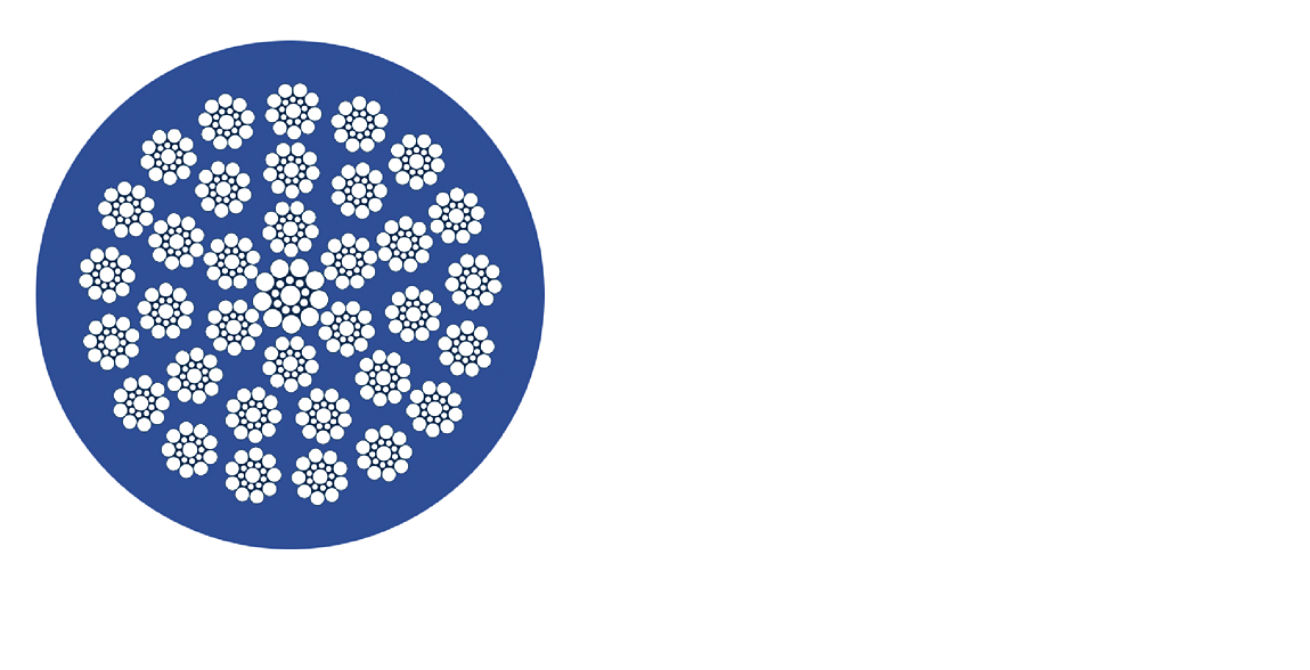

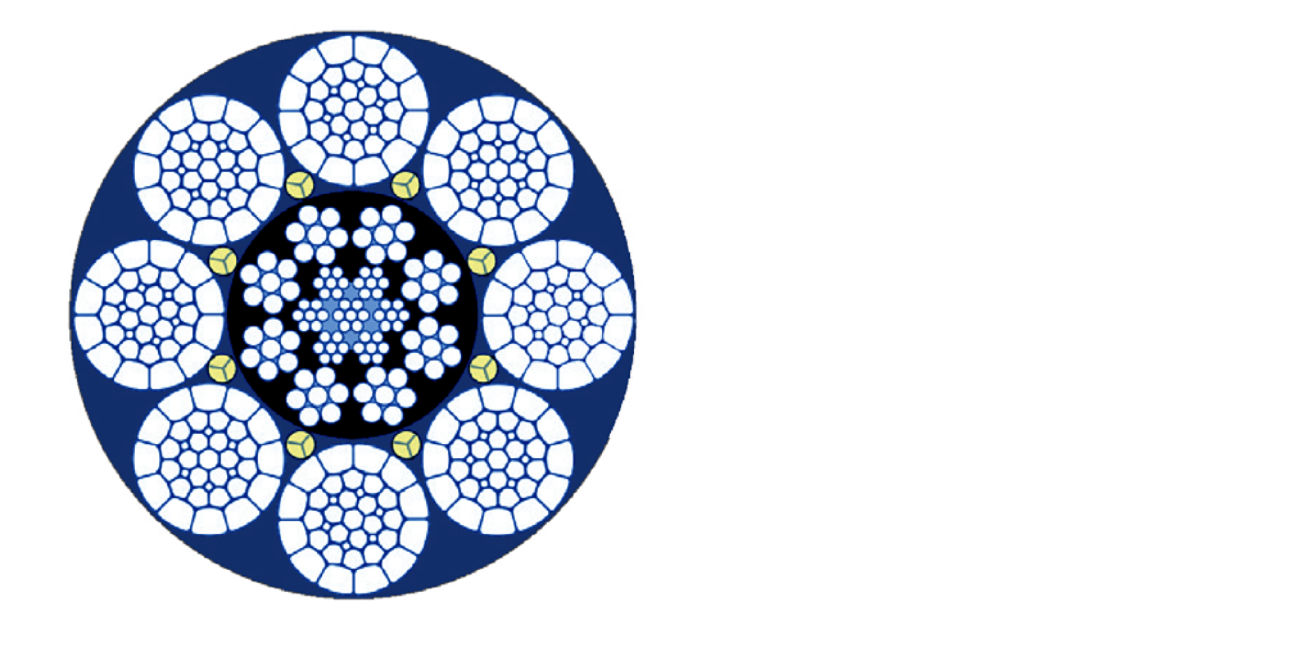

A 34x19 construction provides improved flexibility and an approximate natural loop to rope ratio of 45-1. Multi-strand spin resistance and plastic enhancement allow for smooth in-service operation, significantly reduced rope torque and stretch, and less movement in the shaft whenthe rope is at full speed. Full plastic impregnation improves spin-resistance and eliminates internal cross cutting of the strands which is common to other multi-strand products, thereby extending service life and improving security. Galvanised wire and WRI's patented one-step impregnationand jacketing process, which provides a thick protectiveouter layer of plastic, prevents contaminants fromcorroding the rope and eliminates the need for costly in-field lubrication.