The Bekaert Technology Centre for ropes is a world leading centre of excellence for rope technology development, analysis and verification.

The Bekaert Technology Centre for ropes harnesses the wealth of knowledge Bekaert has acquired serving global industries for more than a century and combines this with significant investments in personnel, unique test equipment and forensic laboratories.

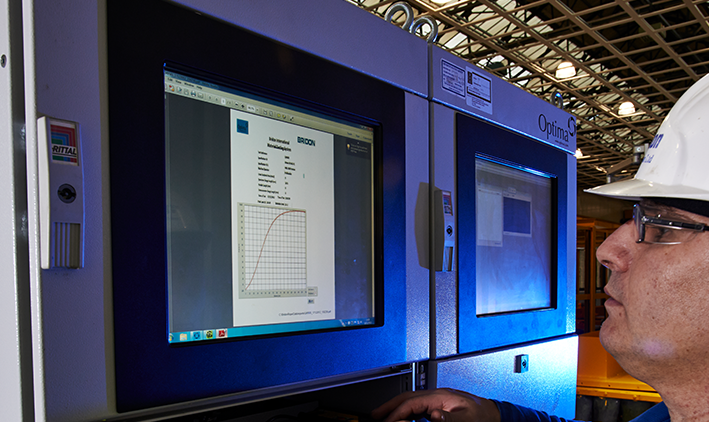

State of the art facilities

The Bekaert Technology Centre’s unique range of purpose-built test equipment, forensic laboratories and bench marked processes enable our dedicated rope engineers and material scientists to accurately capture and quantify operational rope data that has previously not been possible.